| Traditional Welding Methos | LightWELD Laser Welding & Cleaning | |

|---|---|---|

| Speed | Average | Up to 4X Faster than TIG |

| Quality | Depends on user experience | Consistent high-quality results |

| Learning Curve | Steep | Quick and easy |

| Material Flexibility | Limited with consumables changes | Wide range with no set up |

| Distortion & Deformation | High | Very Low |

| Heat Affected Zone | Large | Small |

| Wobble Welding | No | Yes - up to 5mm additional weld width |

| Pre- and Post Weld Cleaning | No | Yes - up to 15mm cleaning path |

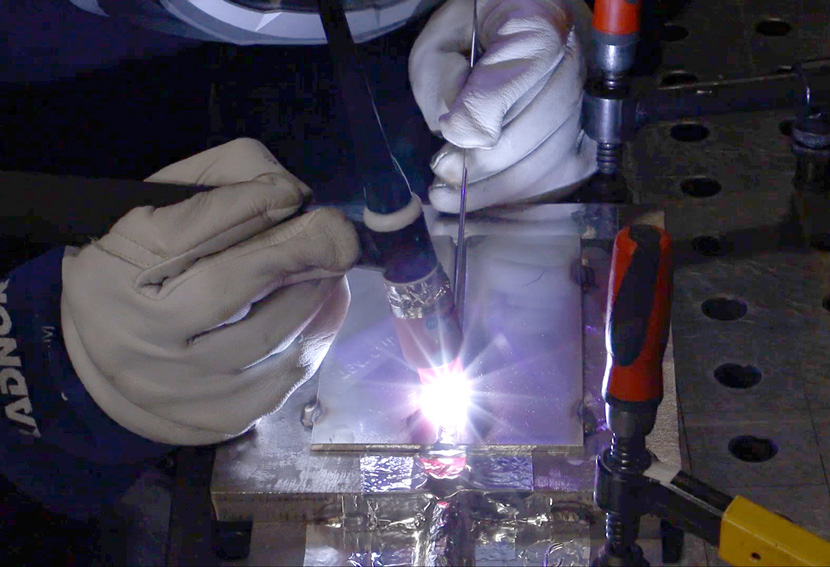

TIG welding is a time-consuming, two-handed welding method that requires an experienced, highly-skilled operator. TIG welding may generate extreme heat that deforms thin materials, produces poor visual finishes, is difficult when welding copper,and limited when welding metals of dissimilar thicknesses.

MIG welding requires consumable wire, material pre-cleaning and beveled joints for thick metals for full penetration. Travel and work angles are limited and vertical positions are extremely challenging.

LightWELD enables dramatically faster welding, is easier to learn and operate, and provides higher-quality, consistent results across a wider range of materials and thicknesses than MIG or TIG with minimal distortion, deformation, undercut or burn through.

The low heat input and extensive material and thickness capabilities increase productivity, repeatability, and improve weld quality for operators of all skill levels. LightWELD welds dissimilar metals of different thicknesses with ease and creates aesthetic high-strength joints with minimal or no consumable wire. Plus, LightWELD XC and LightWELD XR offer built-in pre- and post-weld cleaning not found on any traditional system.